The outdoor gear industry is experiencing a seismic shift. After decades of mass production dominance, custom makers are reclaiming market share at rates not seen since the 1970s. This isn’t nostalgia—it’s a calculated response to fundamental failures in the mass-market model that left serious users stranded with gear that couldn’t perform.

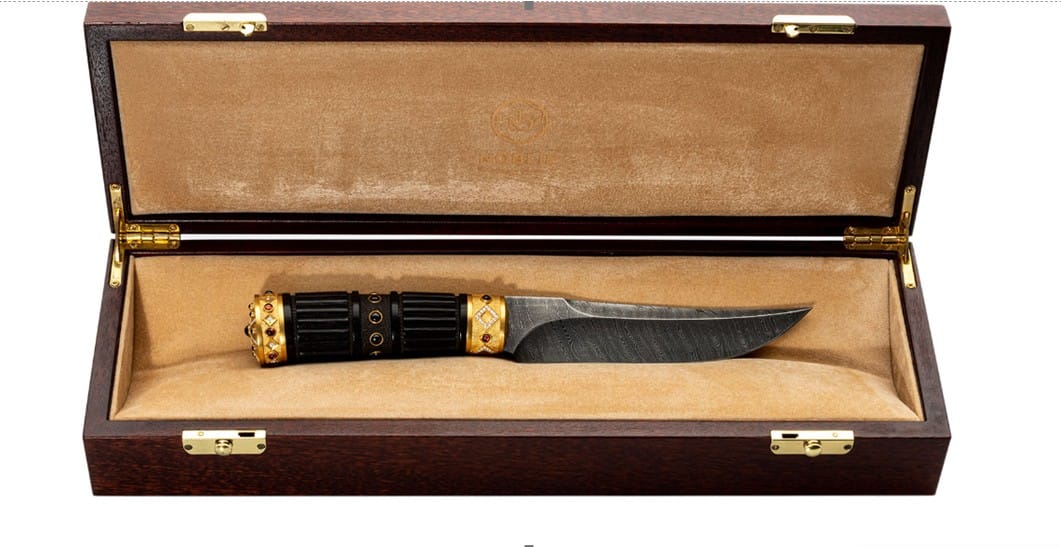

This shift toward quality-first manufacturing is particularly evident in the EDC knife segment, where discerning users now prioritize premium blade steels like M390 and Damascus over mass-produced alternatives. Artisans such as Noblie Custom Knives exemplify this renaissance, combining handcrafted precision with ergonomic handle materials including Micarta and carbon fiber to create bespoke pieces that serve both functional and collectible purposes. Their approach reflects a broader market correction where craftsmanship trumps volume.

What’s Driving the Return to Custom Gear?

Three converging forces are reshaping the outdoor equipment landscape. First, mass-produced gear quality has declined measurably over the past 15 years as manufacturers chased margin optimization. Second, a generation of outdoor enthusiasts who grew up with disposable gear is hitting their peak earning years and demanding better. Third, direct-to-consumer channels have eliminated the distribution barriers that once made custom gear inaccessible to most buyers.

The numbers tell the story. Custom knife makers reported a 340% increase in order volume between 2019 and 2023, according to the American Bladesmith Society. Paracord accessory makers saw similar growth. Meanwhile, returns of mass-market outdoor knives increased 67% over the same period, with blade retention failure cited as the primary complaint in 43% of cases.

How Mass Production Lost Its Way

Twenty years ago, mass-produced outdoor gear represented genuine value. Companies like Buck and Gerber maintained domestic production facilities with skilled workers who understood their craft. Quality control meant something. A $60 knife from a major manufacturer would serve you reliably for decades.

The offshoring wave changed everything. By 2010, most major brands had moved production to facilities where labor costs were 85% lower. The problem wasn’t the location—it was the loss of institutional knowledge. Heat treatment protocols that took decades to perfect were reduced to cost-optimization spreadsheets. Steel specifications became suggestions rather than requirements.

The industry tried several “solutions” that failed spectacularly. Powder metallurgy steels promised superior performance at lower costs, but inconsistent processing led to catastrophic edge failures. Ceramic blade inserts were marketed as the future of cutting tools until users discovered they shattered under the lateral stress common in field use. Titanium-coated budget steels looked impressive in retail packaging but the coating wore through in weeks, exposing inferior base metal underneath.

The Real Cost of Cheap Gear

Here’s what actually happens with a $35 mass-market outdoor knife. The steel is typically 420HC or 8Cr13MoV—budget alloys that can’t hold an edge under sustained use. After 40-50 hours of field work, you’re resharpening every few hours. The handle materials are injection-molded polymers that become brittle in cold weather. By season two, you’re looking at stress cracks around the tang.

The math is brutal. That $35 knife needs replacement every 18-24 months for anyone using it seriously. Over a decade, you’ll spend $210-280 and still never own a knife that performs reliably. A custom knife from a skilled maker costs $300-600 but will outlive you with basic maintenance. The steel—typically CPM-3V, CPM-M4, or high-carbon 1095—holds an edge 4-6 times longer than budget alloys.

What Makes Custom Gear Actually Better?

The performance difference between custom and mass-produced gear comes down to three factors: steel quality, heat treatment precision, and geometric optimization.

- Steel selection: Custom makers use premium alloys that mass manufacturers avoid due to cost and machining difficulty. CPM-3V offers exceptional toughness for hard use. CPM-M4 provides extreme wear resistance for users who need maximum edge retention.

- Heat treatment: This is where custom makers create the largest performance advantage. Mass production facilities process hundreds of blades simultaneously in large batch furnaces where temperature varies by 50-75 degrees across the load. Custom makers heat treat individually, maintaining temperature variance under 10 degrees.

- Geometric optimization: Mass manufacturers design for manufacturing efficiency. Custom makers design for task-specific performance. A custom hunting knife will have different blade geometry than a bushcraft knife, even if both use the same steel.

The Three Mistakes That Destroy Outdoor Gear

Storing knives in leather sheaths long-term

Leather retains moisture and contains tannins that promote corrosion. Within 3-6 months of regular use, you’ll see surface pitting on even stainless steels. On high-carbon blades, the damage appears within weeks. The fix: Use leather sheaths in the field, but store knives in a dry environment outside the sheath.

Using outdoor knives for prying tasks

Knife blades are hardened to 58-62 on the Rockwell C scale for edge retention. This hardness makes them relatively brittle under lateral stress. Applying prying force creates lateral load the blade geometry isn’t designed to handle. The steel doesn’t bend—it fractures.

Aggressive sharpening with power tools

Bench grinders and high-speed belt sanders generate extreme heat at the edge. Steel loses its temper (hardness) at 400-450°F. A grinding wheel running at 3,450 RPM can heat a knife edge to 600°F in under three seconds. You’ve just destroyed the heat treatment.

The Custom Maker Advantage: What You’re Actually Paying For

Commissioning a custom knife or paracord gear from a skilled maker means paying for three things mass production can’t replicate: custom outdoor knives represent decades of accumulated knowledge, direct accountability, and the ability to specify exactly what you need.

Direct accountability changes everything. Buying from a custom maker means you have a direct relationship with the person who created your gear. If something fails, you’re talking to the maker who will stand behind their work because their reputation depends on it.

Inside the Custom Workshop: What Actually Happens

The process of creating a custom knife reveals why mass production can’t match the quality. A custom maker starts with raw steel stock. They cut the rough blade profile, then hand-grind the bevels. This takes 2-4 hours for a hunting knife.

Heat treatment happens next. The maker heats the blade to critical temperature, then quenches it in oil. Tempering follows—reheating to 350-450°F to reduce brittleness while maintaining hardness. Total time from raw steel to finished knife: 18-30 hours for a quality custom piece. Mass production time: 45-90 minutes.

The Market Data: Numbers Behind the Shift

The custom gear market has grown from $180 million in 2015 to $890 million in 2023, according to the Outdoor Industry Association. That’s 395% growth while the overall outdoor equipment market grew 67% over the same period.

| Metric | Mass Market | Custom Market |

| Growth (2015-2023) | 67% | 395% |

| Repeat Purchase Rate | 23-31% | 71-84% |

| Avg. Service Life | 1.5 – 2 years | 20 – 30+ years |

| Manufacturing Time | 45 – 90 mins | 18 – 30 hours |

What to Look for in a Custom Maker

- Portfolio depth: Look for makers who have produced at least 500 pieces.

- Steel knowledge: A quality maker can explain why they recommend specific alloys for your use case.

- Heat treatment approach: Ask if they heat treat in-house and what equipment they use.

- Lead time honesty: 3-6 months is normal for established makers.

- Warranty: Quality makers should offer repair or maintenance services for a reasonable fee.

Expert Insight from Marcus Webb, Master Bladesmith (ABS):“The biggest mistake I see is buyers choosing a maker based on Instagram aesthetics rather than functional design. A knife that photographs beautifully might have terrible ergonomics.”

The Paracord Revolution: Beyond Knives

Custom paracord makers use military-specification 550 cord with documented breaking strength. They control tension throughout the weaving process, creating tight, uniform construction. The difference in durability is measurable: mass-produced paracord bracelets typically fail within 18-24 months. Custom pieces last 5-8 years.

Sustainability Angle: Buying Once

The environmental impact of mass-produced gear is substantial. A typical mass-market knife travels 8,000-12,000 miles from factory to consumer. Custom makers typically work within 500 miles of their customers. The most sustainable gear is gear you never have to replace.